|

The Fantastic Kuranda Machines The Benefits of having a SUPER SOPPER POWERED MACHINES: MANUAL MACHINES: TOW BEHIND

MACHINES: OTHER: |

Welcome to the home of the original Super Sopper * Since 1974 * We stay ahead of the copycats We are innovative with new machines |

|

To contact us: Email: sales@supersopper.com.au Phone: +61 300 956 044

(outside Australia) Phone: 1300 956 044 (within

Australia) |

|||||

|

|

||||||||

|

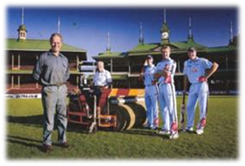

Gordon Withnall, inventor

of the Super Sopper

Len Withnall, son of Gordon

The

Harry Brind MBE, Pitches Consultant, English Cricket Board

Tom

Parker, Curator, Sydney Cricket Ground

|

History of the Super Sopper In 1974 my

father was playing golf at Liverpool Golf Course in Sydney when his ball

landed in a large puddle of water. "Come on Gordon, you're an inventor:

invent a machine to remove all these puddles!" said his friend Tom. I

had been working for my father's business for only about three years when he

came into work the next day and said: "Len, get some of that perforated

metal lying down the back of the shed and roll it into a cylinder". I

looked at my work-mate and said: "Here we go again!" as I knew that

dad was always working on new inventions. The first machine was made in three

days, it was roughly the same size as the modern day 'Sandpiper'. My father

applied for, and received a world patent for the 'Super Sopper'. It was

interesting for me to look at all the water removal inventions over the last

one hundred and fifty years. Some used rollers etc., but none squeezed the

water through the perforated cylinder into a holding tank. This was a world

first! At that time

there was a television program on ABCTV called 'The Inventors'. During that

year of 1974 the 'Super Sopper' machine was entered and was voted the best

machine of the night. I distinctly

remember Di Fisher asking 'Does it come in any other colours?'. The Super

Sopper then made it to the end of year finals, where it came second to a

'so-called' petrol saving device that was fitted to a car's carburettor. From the

ensuing publicity from this program, we started to sell about fifty small

machines each year to schools, councils, tennis courts and cricket clubs. One day in

1979 my father received a phone call from Ian Johnson, who was the arena

manager at the Melbourne Cricket Ground. He wanted Gordon in Melbourne the

next day to discuss inventing a large roller which could dry the entire MCG

ground. We had

worked on a few prototypes previous to this but they had not been successful

yet. Gordon struck on the idea of having two large rollers in tandem with the

driver, motor and drive mechanism mounted between the rollers. Its appearance

was not dissimilar to Fred Flintstone's automobile. The first

machine was going to have a clutch and an FJ Holden gearbox, but hydraulic

drive was becoming popular and had many advantages over earlier drive

mechanisms. The idea was

to distribute the weight evenly over the whole machine and keeps the overall

gross weight as light as possible, thus not damaging the hallowed turf. Lightweight

tube was employed in a truss and this technique is still used today. The

original prototype had a V-belt drive and aluminium pulleys. We realised soon

after, that this just wasn't strong enough, so we went to heavy-duty double

row industrial chain. We used a

'Southcott' hydraulic pump and various other parts which enabled us to

deliver the first whale to the MCG. That year in

Melbourne it was very wet, but the MCG was always dry thanks to the Super

Sopper. It didn't

take long for the word to get out. All the VFL clubs in Melbourne purchased a

'Whale' Super Sopper, as well as the racecourses all over Australia. I've

actually driven from Sydney to Melbourne fifty times delivering 'Whale'

machines. Harry Brind,

curator of 'The Oval' in London, was in Australia at the time on a 'fact

finding' mission and arranged to get a demonstration of the 'Whale' Super

Sopper at the MCG with Jack Lyons, curator at the MCG. Harry was so

impressed by the amount of water removed by the ‘Whale’, which he flew to

Sydney the next day and ordered one to take back to England. So now we

had a machine in England. This led to 'Lords' and 'Canterbury' Cricket

Grounds buying a 'Whale' each. 'Lords' now have six 'Whales' with some on

trailers for transport to other grounds. Cricket

playing countries from around the world saw these machines and now there are

at least one or two 'Whales' at each ground. In 1984 a

Japanese company approached us and started purchasing 'Whales', 'Sandpipers'

and 'Minnows' in large quantities. At one time we were sending six hundred

'Sandpipers' a year to them. 'Sandpiper's

have been used with fantastic results on synthetic grass tennis courts

especially when tennis clubs have a tournament coming up and they have

torrential rain just hours before play. A 'Sandpiper' can dry an entire

tennis court within fifteen minutes. Over the

years the only trouble we have had with 'Whales' is people not treating them

kindly e.g. bashing into goal posts and fences, and failing to undertake

regular maintenance. The hydraulic system has proven to last twenty-five

years or more and we can change the petrol or diesel engine after many years'

work. We have now

sold one hundred and twenty 'Whales' worldwide and have exported to ten

different countries. In 1995 my

father retired and sold the factory and land, which had become a residential

area. I moved the business to Taree, Mid-north coast, NSW, about four hour's

drive north of Sydney. Business has started to boom again as more people hear

about the Super Sopper and what it can do. Les Burdett at Adelaide Oval uses

a 'Sandpiper' to construct cricket wickets. He removes the excess water,

after the initial irrigation to permit the heavy pitch roller to start

rolling sooner. We sell 'Sandpiper's

also to multi-storeyed building sites, where the walls aren't finished yet.

The wind blows the rain onto the concrete floors preventing work to continue.

The Sandpiper quickly dries the pools of water. Also we make

a machine , the 'Sandpiper Industrial', that picks up oil, kerosene and

petrol spills. I will I

remember that day in 1974 after my father played golf, and to think my whole

working life was making 'Super Soppers', and having lots of fun on the way. Len Withnall

Kuranda

Manufacturing 11 February

2000 |

|||||||

|

|

|

|||||||

|

||||||||

|

||||||||

|

||||||||

|

Email: sales@supersopper.com.au Phone: +61 300 956 044 (outside Australia) Phone: 1300 956 044 (within Australia)

| ||||||||